We spoke with Osama Khan, the founder and CEO of the startup revolutionizing the global supply chain, MonoLets.

Osama:

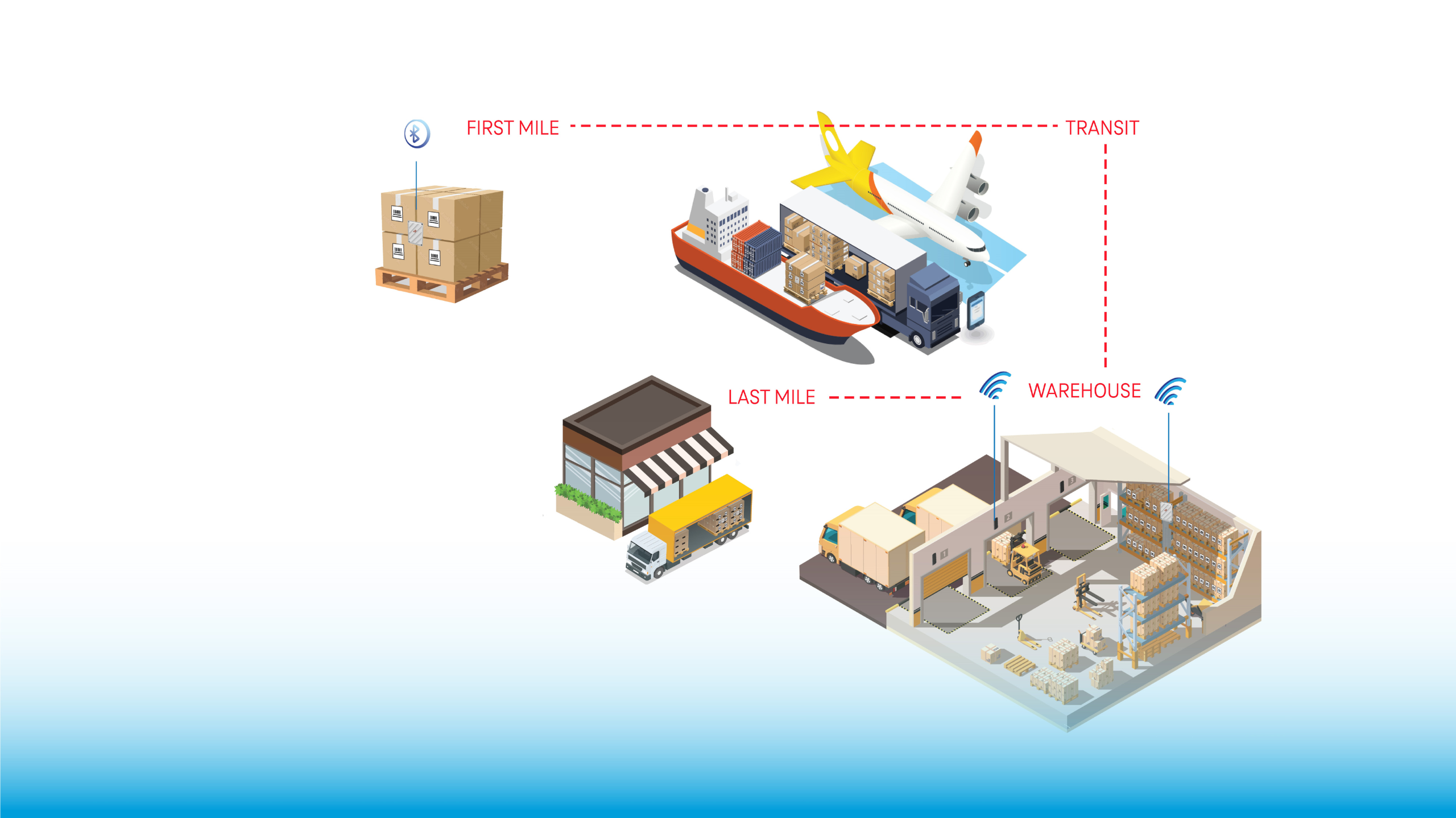

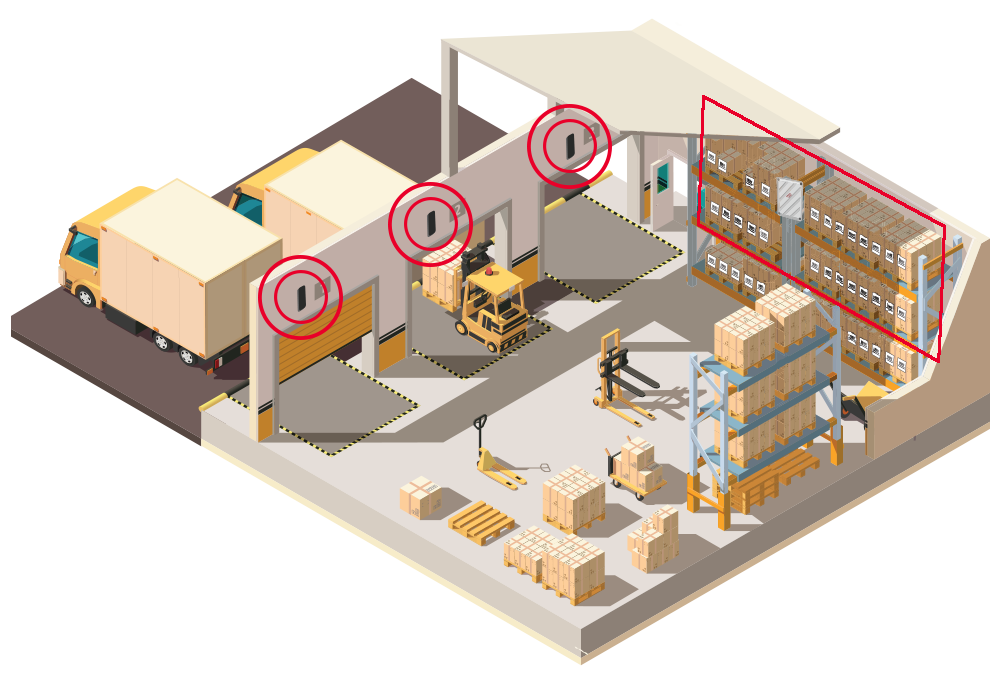

At a very high level, we are creating a real-time item-level supply chain data platform. We are a full-stack solution provider that offers hardware, software, and open APIs that provide access to this data to customers. We provide both the indoor location of an asset and the GPS location in transit, 100% inventory accuracy and asset condition data for example, information about temperature (which would be useful for pharma supply chains, cold supply chains and food supply chains).

Osama:

Our vision is to track commerce globally — this is a very ambitious vision, mainly due to the complexity of global supply chains. In order to accomplish this, we have had to make some breakthroughs in terms of the current state of the hardware and software to track supply chains. Over five years of work at the University of California, Berkeley has been spent asking ourselves: how do we design new radios which have extremely long battery life, are extremely reliable and which can be deployed at scale?

MonoLets has introduced a Bluetooth shipping label — this looks like a normal shipping label you’d get from FedEx or UPS but it has active electronics in it (Bluetooth chip, temperature sensor, etc). Once the device is activated it starts communicating asset data to our cloud.

Osama:

Largely because the collaboration is a great strategic fit — we create local networks for the assets and the data is being transported using Bluetooth communication technology, but we still need to send information to the cloud using backhaul communication. For the uninitiated, backhaul communication refers to the links that connect the core networks with wireless smaller networks closer to the edge — it connects local networks with global connectivity. Deutsche Telekom could be our key partner in providing this connectivity in the European market as we further solidify our commercial relationship.They’ve also begun to work with us as a channel partner (who introduces your solutions to clients they have a pre-existing relationship with) and we look forward to collaborating with them more in this way.

Osama:

They have been introducing their clients to our solution. Beyond this, they have a technology demonstration center in Berlin, the Werner-von-Siemens Centre, where they’ve given us an enormous 15 meter by 15 meter area to carry out a demo of our technology.

So far that system has been running for almost a year and they have been bringing their clients there for demos, asking them if they have any questions, and directing them to us. Going forward, we will be working with them more closely to do more targeted outreach. Beyond this, hubraum has invested in us twice, both in seed funding rounds — once in 2020 and once in 2022.

Osama:

Our solution is now commercially available, ie. it has met market requirements and quality issues have been resolved. I think that's the biggest milestone that we have achieved over the last several years. Now we’re in the pilot stage with our clients. It’s a good feeling, because thanks to our collaboration, we have done several iterations of this product over the last several years and we've done major upgrades both in terms of hardware and software. This means we have a pretty healthy sales pipeline, so in the next six months our goal is to convert the pilot deployments into commercial purchases.

We also spoke to Andreas Dönges, an innovation transfer manager at hubraum, about his time supporting MonoLets.

Andreas:

By bringing together startups with Deutsche Telekom Group business units that might be interested in the startup’s product or services.

In the case of MonoLets, I made contact with T-Systems, and in particular with the Werner-von-Siemens Centre in Berlin, to give MonoLets the opportunity to present their product to T-Systems customers.

Lutz Schneider, a Product Owner Autonomous Logistics at T-Systems also talked to us about why the collaboration with MonoLets was so valuable.

Lutz:

Usually at T-Systems, we’re technically driven: we work at a meticulous pace, and we have a precise structure as to how we do things. MonoLets is based in the US and has an agile workflow — it was great to work at a faster pace with them, we were able to get their demo up and running in Berlin promptly and get feedback from our customers which we could put back into developing the product further.

Lutz:

The use of state-of-the-art technology from MonoLets enhances the customer experience at the Telekom Industry Hub in Berlin. Here, customers are shown through a supply chain story — they are guided through an example warehouse and shown different demonstrations of products which could optimize the supply chain experience. Prior to MonoLets, we had a missing puzzle piece — we had to source the various services they offer from a number of different suppliers. But MonoLets have solved this issue, acting as a one-stop shop for tracking a product from manufacture to delivery.

Interested and want to know more about MonoLets? For more info, click here.